Flat Presser Le Mochini oa Ovine

Tlhaloso

Lebanta MOFUTA O TSOELA PELE OA TLHOKOMELISO E SEBELISA HO HLAHISA FILA E TSOELA PELE E TSIETSENG THERMOPLASTIC UNIDIRECTIONAL PREPREG BELT LAMINATE, E LOKELANG HO HLAHALA KA BOMELA BA THERMOPLASTIC COMPOSITE MATERIAL motswako oa mefuta e fapaneng ea fiber, e ka sebelisoa.Thermoplastic unidirectional prepreg laminate;Ke poleiti e tiileng e entsoeng ka letlapa le nang le fiber e tsoelang pele e matlafalitsoeng ke thermoplastic unidirectional prepreg lebanta.'Mala o tloaelehileng ke o mosoeu le o motšo.Haholo-holo e sebelisoang ka fiber e tsoelang pele e matlafalitsoeng ka thermoplastic lightweight solutions tse kang thermoplastic composite honeycomb panels;Boto ea moleka oa teraka;Sekoaelo sa betri ea koloi ea motlakase;Boto ea lesela la nkho;Libaka tsa literene, liboto tsa likoloi joalo-joalo

CFRT lakane ke thermoplastic composite lakane entsoe ka CFRT tsela e 'ngoe lesela ho ea ka 0 °,45 °,-45 °,90 ° le 'ngoe kapa ho feta metsoako ka mor'a ho chesa le ho batang tobetsa.E ka boela ea kopanngoa le lisebelisoa tse ling tsa mantlha tse sebetsang hantle, tse kang boto ea khekhe ea linotši, foam ea polyurethane, balsa balsa, boto e tiileng ea lehong, joalo-joalo, kapa ka thepa e sa lohiloeng ho etsa boto e ncha ea sandwich.

Melemo: Fiber e tsoelang pele e fana ka matla a holimo-limo le ho satalla;Ts'ebetso e ntle ea ho kuta ea interlaminar, matla a ts'ebetso e phahameng;The layering mode, botenya, ho matlafatsa mofuta oa thepa le fiber volume content ea lakane e ka etsoa ho finyella litlhoko tsa bareki liindasteri tse fapaneng;Sebaka sa lihlahisoa ntle le lijo-thollo tsa lesela;Ho hanyetsa kutu, ho hanyetsa hlobo, ho bonolo ho hloekisa, ha ho amehe ke lihloekisi tsa lik'hemik'hale;Weldable, bonolo ho seha, kenya le ho lokisa;E ka ba ho tjhesa ho tobetsa ho bopa, ho etsa potoloho e khuts'oane;E ka nkela sebaka sa thermosetting khalase ea polasetiki e matlafalitsoeng, aluminium le lakane ea tšepe e sa hloekang, 'me e loketse lipalangoang tse bobebe;Tšireletso ea tikoloho e tala, e ka sebelisoang hape, nts'etsopele e tsitsitseng.

Mohlala le parameter

| Mohlala | SPX1700 | SPX2300 | SPX3000 | SPX3400 |

| Bophara ba lebanta(mm) | 1700 | 2300 | 3000 | 3400 |

| Bophara bo sebetsang(mm) | 800-1550 | 1450-2000 | 2000-2750 | 2300-3050 |

| Bolelele ba mocheso(mm) | 1500-3000 | 1500-3000 | 2500-4000 | 2500-4000 |

| Mokhoa oa ho futhumatsa | Ho futhumatsa motlakase | Ho futhumatsa motlakase Ho futhumatsa oli | Ho futhumatsa motlakase Ho futhumatsa oli | Ho futhumatsa motlakase Ho futhumatsa oli |

Mochine oa khatiso o tloaelehileng

Mochini o tloaelehileng oa khatiso (Boima ba lihlahisoa: 0-1600 GSM)

Mochini oa khatiso o phahameng

Mochini o phahameng oa khatiso (Boima ba lihlahisoa: 1600-2200 GSM)

Ontong

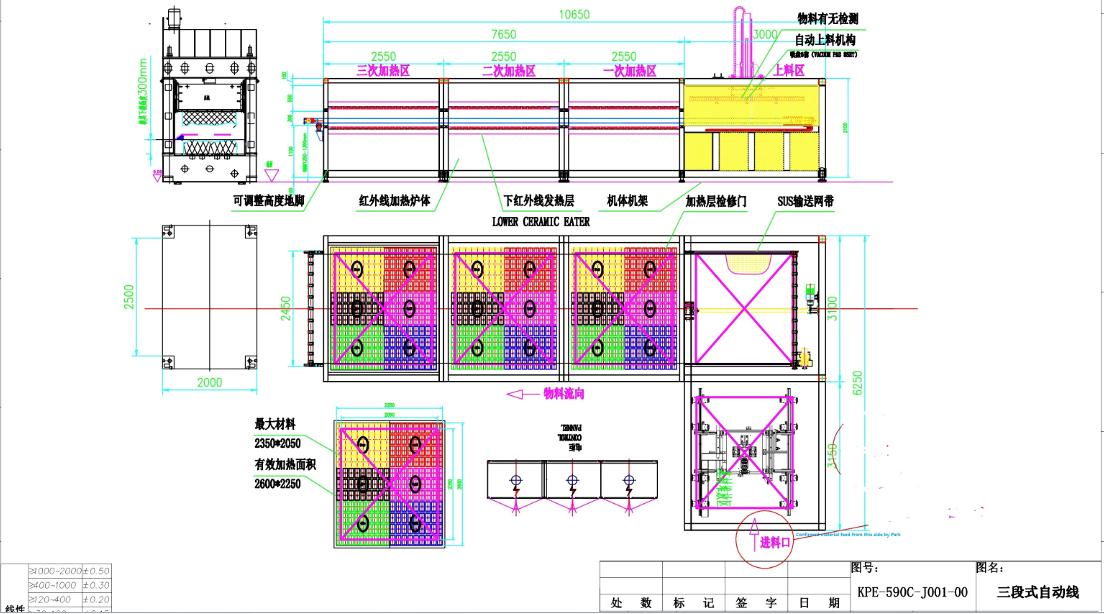

Mohala ona oa othomathike o khona ho sebetsana le liphutheloana le lihlahisoa tsa lishelefo ho fana ka mefuta e fapaneng ea likoloi.E laoloa ke ho kenya PLC.

1. Seteishene sa ho jarolla thepa ka boiketsetso se na le likarolo tse peli tsa ho kenya.E ipapisitse le lisebelisoa tsa KEC tsa needlepunch le likopi tsa vacuum ho etsa mesebetsi ea ho khetha le ho beha sebaka ho lumellana le mefuta e fapaneng ea thepa.Ho fetola thepa ka othomathike ho thusa ho ntlafatsa ts'ebetso.

2. Ho kopana le heater ho fana ka katleho e phahameng le boemo bo nepahetseng ba thepa, e thusang haholo ho finyella ho futhumatsa ka potlako le ho tsamaisa thepa.

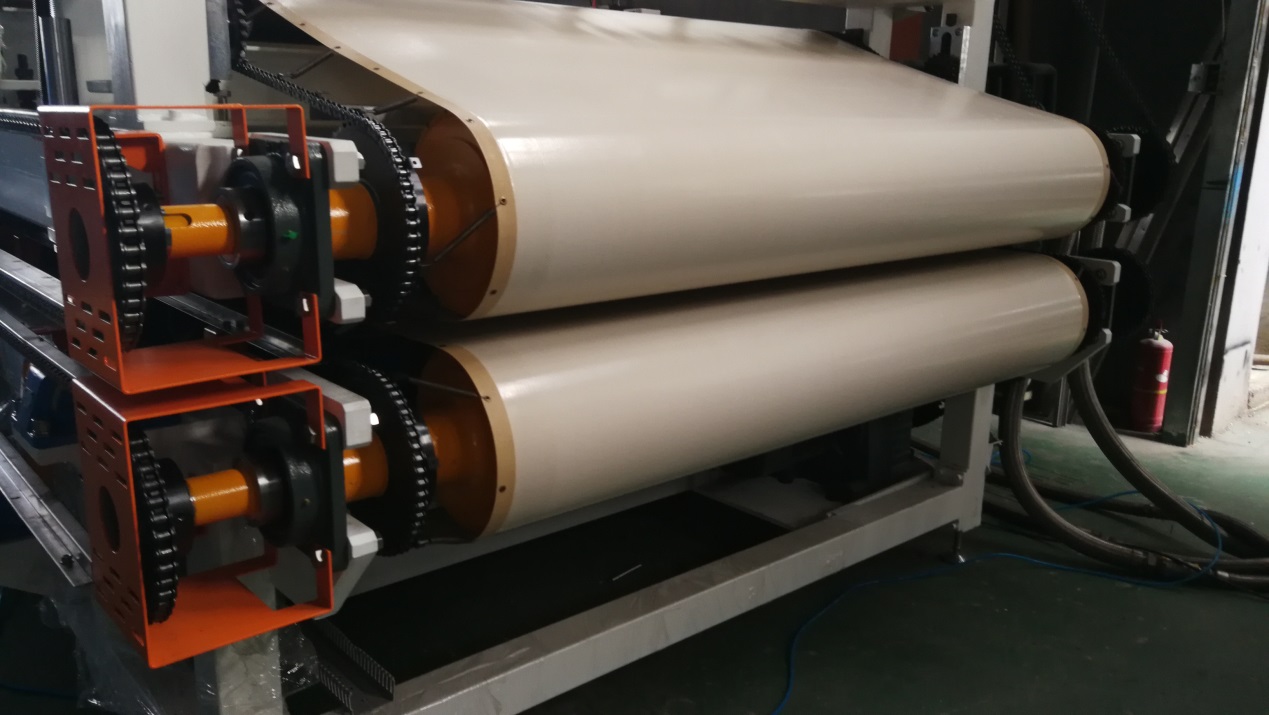

3. Mochine o tsamaisang thepa o sebetsa ka mabanta a potolohang a Teflon ho ea holimo le tlaase ho qoba lintho tse khomarelang holim'a lipoleiti tse futhumatsang tse ka holimo le tse tlaase, tse lulang li hloekile 'me li tlosa matheba habonolo.

4. Mochine o khethehileng oa mochine oa khatiso oa hydraulic o hlophisitsoeng ke sethala se seholo sa ho sebetsa se tsamaisana le mokhoa o potlakileng oa ho koala hlobo e le hore hlobo e ka fapanyetsanoa ka potlako le ho sireletsoa ke konopo e le 'ngoe.

5. Ka mor'a hore masela a roala a kenngoe, a ka khaoloa 'me a isoa mouldingpress ka tsela e iketsang.Ho sa le joalo, sisteme e sa sebetseng ea ho lemoha lintho e ka khaola karolo e fosahetseng ea meqolo ebe e e romella lebokoseng la litšila.

6. Taolo ea hole, tsamaiso e bohlale ea fektheri le ho shebella video ea tlhahiso e ka finyelloa ka mokhoa o pharaletseng ka mokhoa o bonolo ho latela mohala ona.